Satellite Digital Products —— Digital Twin Satellites

A demo illustrates a satellite's large-scale orbital maneuver (from a 550km orbit to a 300km orbit)

Application:

Design and verification of satellites

Automated testing

Intelligent manufacturing

Autonomous navigation of intelligent satellites

In-orbit operation and maintenance

demonstrations and drills, and etc.

- The twin satellite embeds real software for real-time operation and is connected to real-time telemetry data from the physical satellite, running synchronously with it to truly reflect its status. It performs real-time statistical analysis on the status of various satellite components and the surrounding environment. Additionally, it can operate beyond real-time to predict future states, enabling early warning, self-repair, task generation, and autonomous execution.

Digital Twin constellations

A demo illustrates a large-scale-low-altitude moving target surveillance constellation

Application:

Design and verification of constellations

Intelligent operation and maintenance management Multi-satellite task generation and management

Multi-satellite collaborative scheduling

Constellation configuration maintenance

Constellation efficiency analysis

-

The constellation is composed of digital twins technology;

Realistically simulation the outer space environment;

Simulate the process of satellite resource scheduling, and conduct statistical analysis on efficiency and configuration changes of constellation;

Possess real-time operation and super-real-time simulation capabilities.

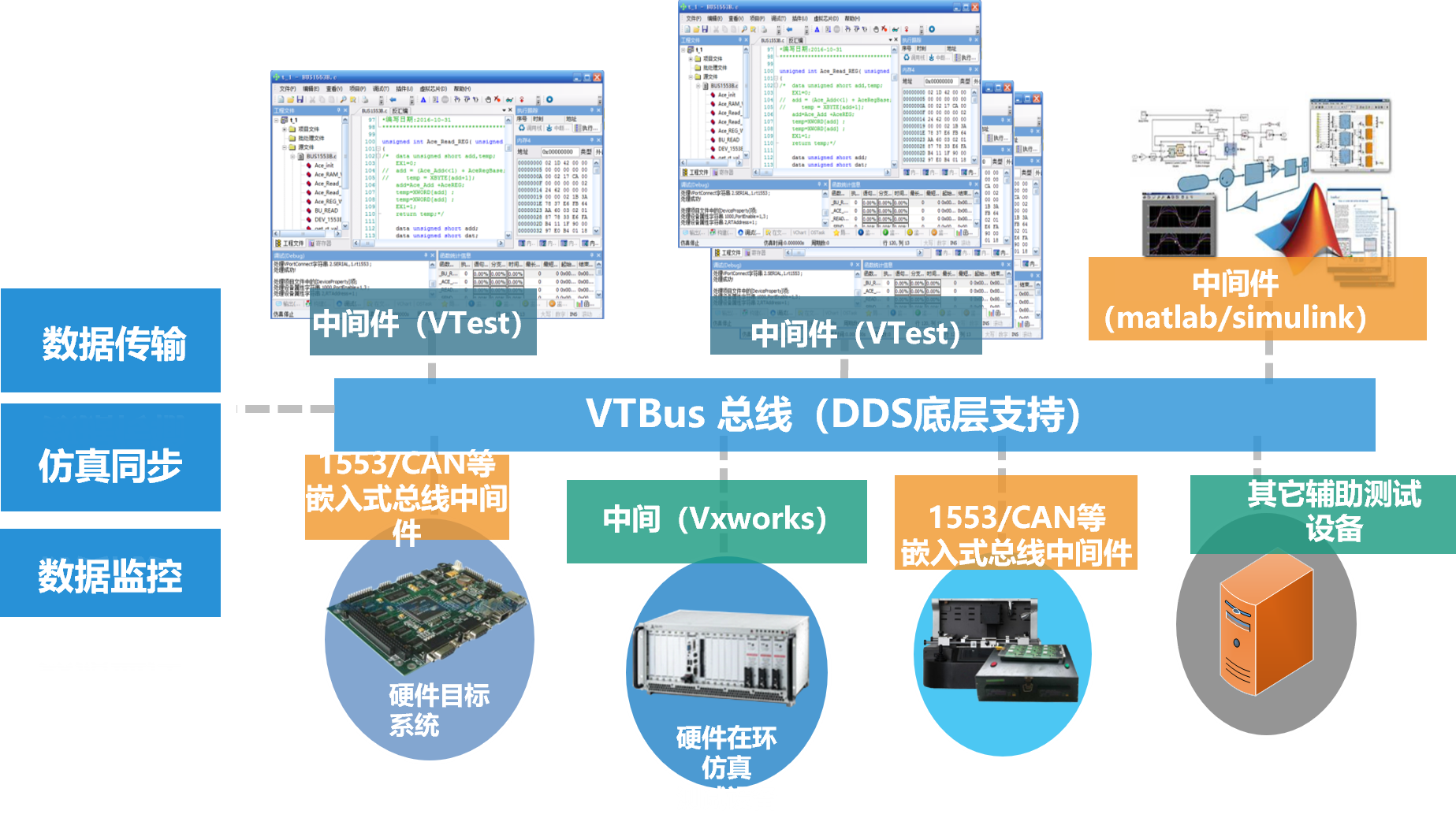

Automated Testing Application

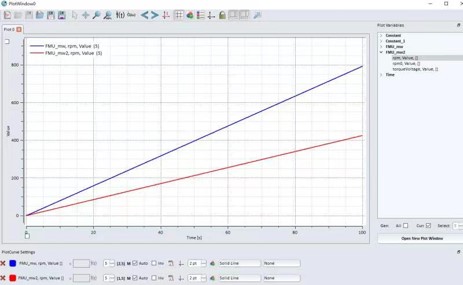

Software Automated Testing System

The built-in satellite digital twin system constructs visualized models of the entire spacecraft, spacecraft components, and the space environment. By utilizing software simulation technology, it realistically simulates the physical environment in which the embedded software operates, forming a virtual system for software debugging and verification.

Satellite Assembly Automated Testing System

The built-in satellite digital twin system incorporates visual models of the entire spacecraft, spacecraft components, and the space environment. It is equipped with physical interfaces and measurement devices, enabling external data-driven testing according to various scenarios during the satellite assembly process. This allows for automated testing tailored to different stages and scenarios of satellite assembly.